At Your Service

CNC

Utilizing the latest conventional, as well as 5 axis and EDM technology, we can quickly (and cost-effectively) produce on-demand parts, models, fixtures, and tools.

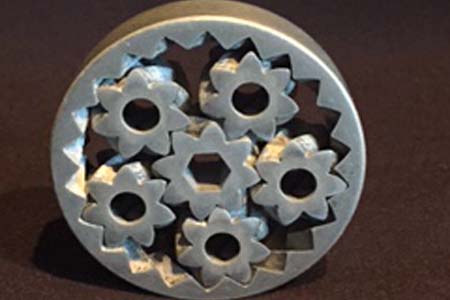

DMLS / DMLM

DMLS is the Additive solution for complex parts that are not viable candidates for conventional manufacturing (inside channels, challenging geometries, assembly reductions). Parts are grown, layer by layer, from powdered metal (particulate is approximately 45 microns in size) in layers from 20 microns, to 70 microns thick. Once built, parts are 99% dense, and may withstand all post processing eligible for cast or machined parts.

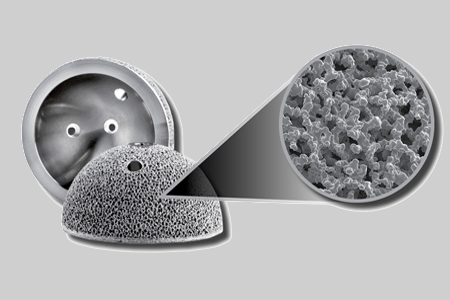

Electron Beam Melting (EBM)

EBM is an alternative additive metal process. The EBM system utilizes a high power electron beam that generates the energy needed to melt the powdered metal. The build chamber is vacuum controlled and the entire bed is heated… resulting in less residual stress than that of DMLS. (Image courtesy of Arcam)

Fused Deposition Modeling (FDM)

FDM is an extrusion-based 3D modeling process that utilizes actual thermoplastics. The material filament is melted and extruded through a heated nozzle. The parts offer great durability and thermal properties. (Image courtesy of Stratasys)

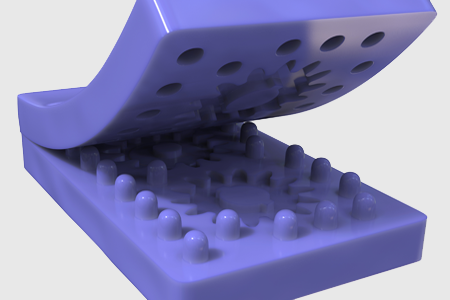

Polyjet

Polyjet is a material jetting process, distributing droplets of the building material to form the geometry dictated by your CAD. Polyjet offers high resolution and smooth surface finish. Aside from the rigid material options, there are elastomer material options as well. (Image courtesy of Stratasys)

Selective Laser Sinter (SLS)

SLS is a powder based system, where a laser fuses the powder within the powder bed, dictated by your CAD design. SLS creates light, durable nylon-based parts utilized for both prototyping and production. High heat deflection, durability, strength, and ability to incorporate living hinges make this a very popular technology.

Stereolithography (SLA)

SLA begins with a liquid photopolymer in a vat that is cured by light activated polymerization in the geometry dictated by your CAD. SLA offers good fit / form / function models. Smooth surface finish makes SLA a great candidate for painting and metalizing for show pieces. Ability to offer clear, polished parts, or opaque materials.

Urethane Casting

High accuracy, simulated production parts. Urethanes can simulate virtually any production material from Low-density foam and rubber, to injection molded polymers and elastomers. Equipment: MCP Vacuum Casting Equipment. MCP-001 and MCP-004, with custom extension chamber to produce parts up to 6 feet long. Custom Vacuum/Pressure casting chambers. 2 – AST RIM Pressure Casting dispensers.

Digital Light Synthesis (DLS)

DLS is a photochemical process that carefully balances light and oxygen to rapidly produce parts. Light is projected through an oxygen-permeable window into a reservoir of UV-curable resin. As UV images are projects, the part solidifies and the build platform rises. The DLS process involves a secondary curing stage embedding a second heat-activated reactive chemistry in the materials. DLS parts maintain strength and mechanical properties in all directions. Material options include rigid, flexible, elastomeric and high temp options.

Multi-Jet Fusion (MJF)

MJF is an additive process where parts are built layer, upon layer. MJF uses an inkjet array to selectively apply fusing and detailing agents, following model design, across a bed of nylon powder. This is then fused by heating elements into a solid. After each layer, powder is distributed in an additional layer and the process continues until the part model is complete. Parts are strong, accurate, and have a quality surface finish.