Community

Using 3D Printing in My Personal Life

3D printing has not only provided sustenance to my family, but it has now provided great blessings as well.

I began my Additive Manufacturing journey by working with surgeons to utilize patient-specific bone models and surgical guides for added value in complex orthopedic interventions. The surgeon’s feedback relative to the benefit of utilizing the technology for pre-surgical planning, and intraoperative reference was extraordinary… both during the surgery, as well as post-surgery.

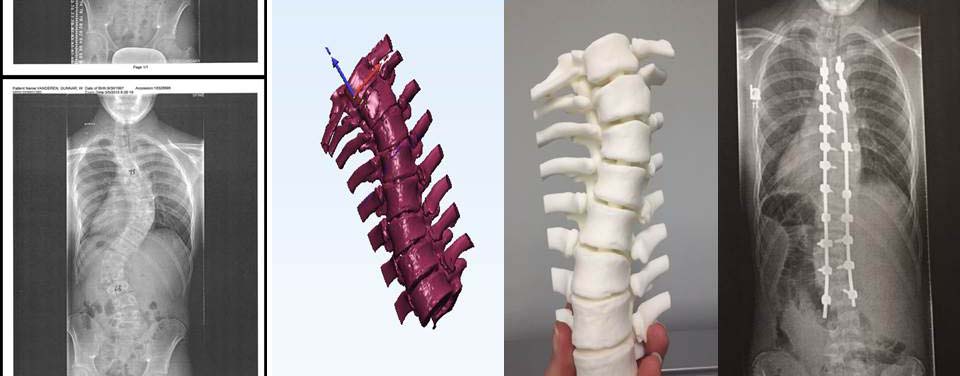

The attached photo captures a journey taken with my own son, who had severe scoliosis. He wore a brace for 16 years that was designed to “hold” the curve and prevent extraordinary progression, to allow for as much organic growth as possible. In 2015, it was decided that surgery was inevitable and imminent. Prior to surgery, a CT scan was ordered. I took the liberty of taking the DICOM images from the scan and having them converted into stl files. From those files, a printed model of his spine was grown via SLS technology (Nylon PA is a material that may be autoclaved and is allowable within the sterile field). This model was then delivered to his surgical team to act as a pre-surgical reference. As you can imagine, the only 3-Dimensional view the surgeon gets is that which is revealed after the patient has been opened up. This model allowed the surgeon to view the vertebrae, in whole. Was the bone model a necessity for scoliosis surgery? Perhaps not, but it certainly added another arrow to the surgeon’s quiver of tools walking into that OR in April 2015.

From a parent’s perspective…. Watching your child wheel away from you can be an overwhelming sensation. However, knowing that our surgical team had great experience, great knowledge, and one extra resource was reassuring. Thankfully, the surgery was a great success and his healing has been fast and without incident.

3D printing changes the way we design, the way we engineer, the way we repair… its application and ability to revolutionize is exceptional!

An Unlikely Collaboration That Resulted in Advances in Medical Models and Devices.

One of the benefits of attending conferences is the opportunity for networking. These events are about meeting peers in similar and adjacent fields, and sometimes can inspire new ideas. Shannon VanDeren, owner and president of Layered Manufacturing and Consulting, as well as vice president of the Additive Manufacturing Users Group (AMUG), explains how one chance meeting led to an unlikely collaboration that resulted in advances in medical models and devices.

Medical AM Ramping Up

In 2016, medical and dental contributed $667 million to the $6 billion-plus worldwide additive-manufacturing (AM) market, with North America—boasting an advanced healthcare infrastructure and sophisticated R&D facilities—claiming more than one-third of the segment. So reads Wohlers Report 2017, a worldwide AM review and analysis. Medical- and dental-AM applications continue to rise, as does the use of metal in these applications—metal accounts for about one-third of material use in medical-AM work. In fact, the AM medical-devices market is expected to hit $9.8 billion by 2025, according to a new study published by Crystal Market Research, and you can bet that metal 3D printing will increase its share…

3D Printing of Medical Devices: When a Novel Technology Meets Traditional Legal Principles.

A white paper by Reed Smith.

Using Innovative Technologies For Manufacturing Rocket Engine Hardware

Download DocumentCancer Patient Receives 3D Printed Ribs In World First Surgery.

Download DocumentBMW Group expands use of additive manufacturing processes.

With more than 10,000 manufactured parts built into the Rolls-Royce Phantom, the BMW Group has been using components from 3D printers in series production since 2012. The company will continue to expand this pioneering role in the future. The Additive Manufacturing Center at the company’s Research and Innovation Center (FIZ) has also been using these forming processes to produce parts for the new Rolls-Royce Dawn since the start of the year.

General Motors Announces Partnership with Autodesk to 3D Print Parts for EVs

General Motors is aiming to have 3D printed parts inside production vehicles within the next five years.

General Motors (GM) has announced it will collaborate with software company Autodesk to 3D print parts for its new range of electric vehicles. The company hopes by using this cutting edge technology it can achieve its ambitious goal of adding 20 new electric vehicles to its global lineup by 2023.